Back to top

Providing high-quality Cast-Iron bodies, Hardened and Ground Shafts & Bushes, Highly Precise Automotive Parts, Pump Bodies, For CNG Application Manifold etc.

-

Break Drum And Wheel Hub -

Cast Iron Junction Box -

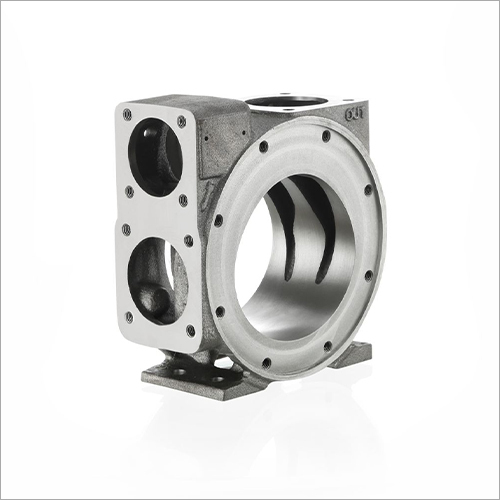

Compressor Parts -

CVT And Gearbox Parts -

Differential Cage And Front Hub -

Hardened And Ground Shafts -

Highly Precise Automotive Parts -

Pump Body -

Tractor Parts -

SS304 Manifold For Cng Application -

Machined Components of Investment Castings -

Machined Components of Steel Castings -

Machined Components of Cast Iron Castings -

Machined Components of SG Casting -

Machined Components of Automotive Parts -

Machined Components of Railway Parts -

Machined Components of Fire Fighting Equipment's Parts -

Machined Components of Aerospace Parts

In the year 1984, Ashish Engineering Works was established as a proprietary unit and began manufacturing and supplying Parts And components. During our journey, we have also developed a wide range of precision engineering parts for the Textile, Agricultural Products, General Machine Tools, Tractors, Marine, Railway, and Aviation Sectors. In the last 30 years, the company has expanded its manufacturing base with innovative and advanced CNC machine tools and evaluation instruments. The company was established by Mr. Ganesh B. Thumar, who is a Gold Medallist in Mechanical Engineering. He aimed to take our company to the top position by offering the best quality

products and services. He strongly believes that customer satisfaction and hard work are the way to success. With his support, we are working as a manufacturer, exporter and supplier of Cast Iron bodies, Hardened And Ground Shafts & Bushes, Highly Precise Automotive Parts, Pump Bodies, Tractor Parts, Break Drum And Wheel Hubs, Differential cage, Manifold for CNG etc.

With continuous hard work, we identified a greater opportunity in the Engine Parts & Components sector and its ever-escalating repeated demands from the OEM and global replacement markets. By successfully meeting the demands of customers, the turnover growth rate of our company got constantly increased, year after year since its inception. Due to the collaborative efforts of dedicated, highly motivated, and quality-conscious employees, we have regularly served the industry.

Currently, the company has its set up of over 18000 square feet, with a 10000 square foot factory building and an 8000 square foot garden and parking. Because of our significant share in local markets and expansion rate in the overseas markets, we, Ashish Engineering Works, have currently become a leading name in the field of Auto Parts & Component markets. The main distinguishing feature of our company is our ability to promptly develop and deliver extremely precise components.

We believe in supplying high-quality products that reduce production costs and help us attain the satisfaction of customers. Furthermore, we are setting benchmarks in the domain due to our constant innovation in conventional machinery to achieve better results, as well as investments in CNCs and VMCs and SPMs to handle large-scale production with speed and accuracy.

With the help of our highly skilled team of engineers and technicians, we have attained a lot in the industry. Our team members work in harmony at the manufacturing site, there is no junior-senior level. This strength provides us with better quality results and reduce the cost of our products.

Quality Policy

At Ashish Engineering Works, we genuinely think that the customer comes first in every business. We strive for complete client satisfaction by supplying precision items, such as, Hardened and Ground Shafts & Bushes, Break Drum and Wheel Hub, Differential cage, Manifold for CNG, Cast Iron Body, Highly Precise Automotive Parts, Pump Body, Tractor Parts, etc. as per the agreed-upon technical and commercial terms.

Product Manufacturing Facilities

We make use of technology to speedily develop the offered products with perfection. We get the desired perfection in the offered products due to use of following machines and equipment in their manufacturing:

- Gang Milling Machines

- SPM Drill Machines

- SPM Tapping Machines

- Gear Shaper [HMT]

- Thread Rolling Machines

- CNC Turning Centers [Mazak-Japan & LMW & Jyoti]

- VMC [Hass- USA & Ace micromatic]

- Centre-less Grinding Machines [Cincinati]

- Cylindrical Grinding Machine [Solco & ace]

- Auto Honing Machines [SUNNEN USA]

- Precision Centre Lathe Machines Heavy duty

- Precision Centre Lathe Machines Light duty

- SPM Milling Machines

- Power Presses

- Tube Polishing Machine

- Burnishing

- Heat Treatment Processes

- Surface Treatment [Zinc Nickel Plated, Hard Anodizing on Aluminium, Blackening, Hard Chrome Plated]

Most Popular Products

- Break Drum And Wheel Hub

- Cast Iron Junction Body

- Compressor Parts

- CVT And Gearbox Parts

- Differential Cage And Front Hub

- Hardened And Ground Shafts

- Highly Precise Automotive Parts

- Pump Body

- Machining Components of Tractor Parts

- SS304 Manifold

- Machined Components of Investment Castings

- Machined Components of Steel Castings

- Machined Components of CI Castings

- Machined Components of SG Castings

- Machined Components of Automotive Parts

- Machined Components of Railway Parts

- Machined Components of Fire Fighting Equipments

- Machined Components of Aerospace Part

ASHISH ENGINEERING WORKS LLP

GST : 24ACHFA5353P1Z2

GST : 24ACHFA5353P1Z2

Plot No. 56, Kothariya R.S. No. 150,Gondal Road,Rajkot - 360004, Gujarat, India

Phone :08071930315

|

ASHISH ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |